Despite the growing use of digital and social media the most common and valued communications channel for business structures is usually good old-fashioned face-to-face interaction. Whether this remains to be so in the mid to long term future remains to be seen.

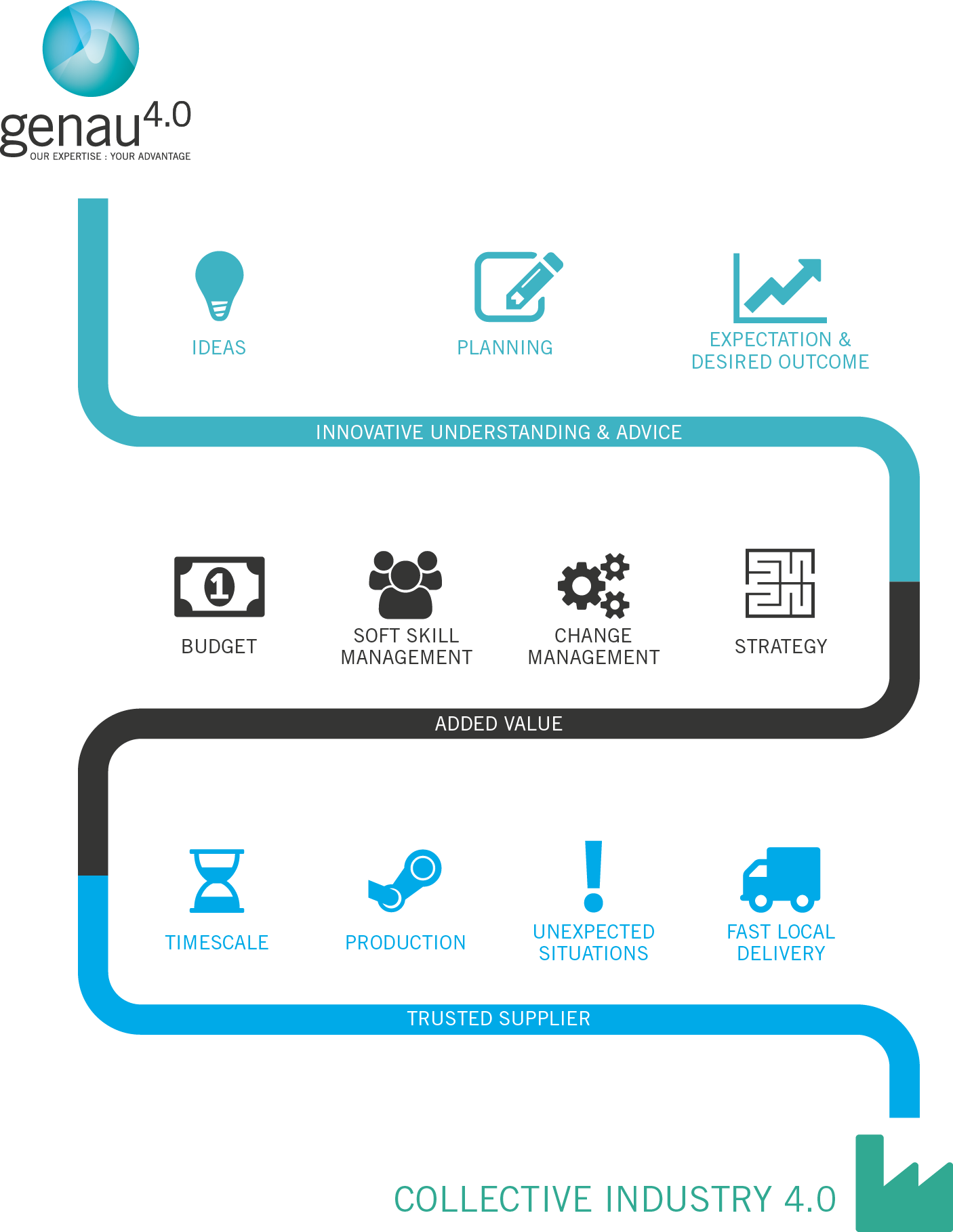

The strength of face-to-face business communication, especially with an external knowledgeable and informed third party, is that it can bring with it an additive unknown factor to both a relationship and a project – wisdom and trust. We all trust the data when it is proved but the application of it into everyday business needs skill and know-how of interpretation. By integrating that understanding, enhanced by previously gained experience, its contribution considerably aids forming a strategy that manages the project and ensures a successful outcome.

Production facilities of all sizes aim to achieve item production at a level to satisfy the orders; those that are already in and being prepared as well as managing any change of item quantity during the process. This Targeted Fill Rate is defined by and ultimately achieved by Maintaining Productive Inventory. The advantage of trusted expertise from an Industry 4.0 supplier being applied to this business model is three-fold.

1. They bring an understanding of networking all components in real-time with a clear vision to meet deadlines. This is based upon a clear context of orientating products and raw materials towards a scalable delivery schedule and an element of autonomy for the client.

2. A precise instruction of procedure creates a global flexibility of prior planning together with a positive critique toward secure production techniques. The result enables agile boundaries to be instrumental in a guaranteed and smart outcome.

3. Most importantly for all stakeholders the integrity of infrastructure is maintained to the highest level in order to secure production. Investment in high quality ensures that market values are upheld and indeed enhanced.

Industry 4.0 suppliers allow smart change through targeting innovative inventory; creating additive growth to fill supply and demand while maintaining a secure vision of the future change.